Cost-Effective Circuit Control in Small Packages

Series 06TR, 09TR and 14TR trimmer potentiometers are a new line of circuit control products from CTS. Also known as trimpots, the series TR trimmer potentiometers are in essence variable resistors and are commonly used for initial circuit calibration. Once a desired resistance value has been chosen, the trimmer potentiometers will maintainthe setting to compensate for any variations that otherwise would occur over time.

In contrast to standard potentiometers, that are designed to facilitate frequent circuit adjustment in applications such as lab instrumentation and panel controls, the TR trimmer potentiometers are intended for so-called “set and forget” use. This product line excels in applications that do not demand frequent changes to the operating current, but rather require initial calibration, after which they will continue to operate based on that setting.

For such applications, the TR series trimmer potentiometers offer not just reliable performance over time, but also enable smaller system designs thanks to their compact size. In addition, these products represent a very cost-effective solution, as they are manufactured and assembled using considerable fewer materials compared to their standard potentiometer counterparts.

In the following, we will examine how the TR series trimmer potentiometers are constructed, how they work, and which applications they are best suited for.

How does a potentiometer work?

Both standard rotary and trimmer potentiometers are commonly employed as variable resistors.

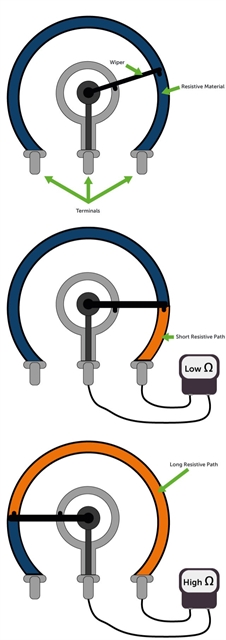

At their core, potentiometers consist of two outer terminals connected by a track made of a resistive conducting material, typically ceramics, high-temperature plastics, phenolics or FR4 epoxy. A third, variable center terminal, placed between the other two, has a rotating wiper attached to it, capable of sliding across the resistive material. Typically, the wiper is operated by an external knob, or it can by turned using a screwdriver.

Applying a constant voltage through the outer terminals will create an electric current, through which a constant current can flow. Positioning the wiper adjacent or close to the outer terminal will result in no or little resistance as the current only has to travel a short distance through the resistive material.

Moving the slider further away from the outer terminal, thereby increasing the distance the current must traverse through the resistive material, will result in an increased electrical resistance. As resistance increases, so will the potential as the current should be constant decrease. As such, potentiometers fulfill their roles as variable resistors, offering manual circuit control through the adjustment of resistance.

What are the advantages of trimmer potentiometers?

While trimmer potentiometers operate according to the same principles as standard rotary potentiometers do, they are set apart by several key factors, the first being the number of subparts they are made of.

In addition to the terminals and resistive track, a regular rotary potentiometer will typically consist of a shaft, bushing, base and mounting plates, a contactor and a stop plate as well as a metal cover that encases the aforementioned parts. This elaborate construction is necessary to withstand the mechanical wear and tear it will be subjected to during operation, as its ideal applications are likely to demand frequent adjustment of the wiper position. Rotary potentiometers for commercial use will typically have a life cycle of 10000 to 30000 rotations while industrial potentiometers can have life cycles of several million rotations.

This will to some extend lower the cost-effectiveness of a standard rotary potentiometer, as well impose certain size limits to the potentiometer design itself and system it is to be integrated into.

In constrast, trimmer potentiometers are primarily intended for applications that do not require frequent resistance adjustment. Instead, trimmer potentiometers will be used for intital circuit calibration, after which they simply function to maintain the selected setting while still allowing for occasional changes to that.

Since they do not need to be as mechanically robust as standard rotary potentiometers, trimpots can be constructed using considerable fewer parts, enabling smaller product units, greater system design freedom and a more favorable price point.

Where are trimmer potentiometers used?

The ability to adjust and regulate electric circuits makes trimmer potentiometers valuable components in numerous applications. Typically, they will be employed as means of voltage regulation or to maintain time or frequency settings across a variety of industries:

The ability to adjust and regulate electric circuits makes trimmer potentiometers valuable components in numerous applications. Typically, they will be employed as means of voltage regulation or to maintain time or frequency settings across a variety of industries:

Industrial

Trimmer potentiometers excel in small system designs such as printed circuit boards (PCBs) where their compact size allows for easy integration. This opens the door for use in numerous industrial applications due to the prevalence of PCBs in that field.

Relays and safety relays that are used in industrial machinery to control high-voltage circuits with low-voltage signals, often dependent on trimmer potentiometers to adjust and regulate parameters such as voltage, current or speed that would influence the relays operation.

Similarly, industrial power supplies and uninterrupted power supplies (UPS) will likely utilize trimmer potentiometers both for calibration, but in particular for regulating the output voltage. They can also be used as part of a voltage divider network, helping establish specific and accurate voltage levels within a circuit.

Motor control circuits that regulate the speed and direction of electric motors will also commonly employ trimmer potentiometers. In variable frequency drives (VFDs), for instance, trimpots can be used to adjust important performance parameters such as acceleration, deacceleration and maximum speed.

Building and Property Automation

Another industry where the use of trimmer potentiometers is a frequent occurence, is building and home automation.

A LED light dimer will use a trimmer potentiometer to help regulate light intensity by increasing or decreasing resistance, while smoke detectors utilize them to set the desired level of sensitivity that will trigger the alarm.

Additionally, they are a common sight throughout building control panels that govern for instance automated doors/gates and elevator/lift movement.

Consumer Appliances

Consumer Appliances

In everyday consumer appliances, there is no shortage of trimmer potentiometers either. Here, trimpots typically serve to control the speed of rotating blades and parts of kitchen applications such as hand blenders and hand mixers, mixer grinders and stand mixers, The same goes for vacuum cleaners, grass cutters and detail sanders.

They may also be used in refrigerator and water heater thermostats, regulating temperature, or in small size audio equipment for volume control.

TR series value-add options and customization

The TR series trimmer potentiometers can be customized in numerous ways to ensure the greatest degree of compatibility with specific applications. They come in one of four different rotor type configurations and with either surface mount (gull wing or j-bend) or thru-hole terminals (four variations).

While the TR series trimmer potentiometers are commonly adjusted using a screwdriver, CTS can also provide mountable shafts for customers whose applications demand it. The shafts can be customized to a great extend as they are typically cast in polymer, offering improved design freedom in terms of geometry. Options for improved rotational life are also available, up to 10,000 cycles.

The resistive taper can be either linear, logarithmic or antilogarithmic, and customers can choose between a wide range of resistances and tolerances. As a special feature, CTS can combine detents and special resistive tracks with silver prints which will essentially short circuit small segments of the track. This creates resistance plateaus that can be aligned with the detents, so that reaching a plateau will generate a clicking sound.

| Series |

Package (mm) |

Power (W) |

Rotational Life (Cycles) |

Resistance (Ω) |

Tech Info |

| 06TR |

6x6 |

0.10 |

1000 |

100

200

5M

|

06TR Datasheet |

| 09TR |

9.8x10 |

0.15 |

1000 |

100

200

5M

|

09TR Datasheet |

| 14TR |

14x14 |

0.25 |

1000 |

100

200

5M

|

14TR Datasheet |